ST-SEWS Real-time Monitoring and Early Warning System of Submarine Optical Cables Hazards

Major Needs: Submarine Optical Cable Applications and Existing Problems

Current Existing Problems

1. Submarine Optical cable resources are already huge, and construction will be more and more in the future.

2. The cost in laying submarine optical cables is huge, cable breakage and damage caused by humans activities in offshore areas occur frequently.

3. The cost of repairing submarine optical cable is huge, each time takes more than 2 weeks, and the average cost is as high as more than 300,000 US Dollars.

4. Currently can only locate breakpoints after a submarine cable is damaged, but cannot conduct real-time monitoring, early warning and event location of potential harmful events to submarine optical cables.

5. The safety and survivability of submarine optical cable systems are fragile, and there is a lack of effective technical method for protection and early warning.

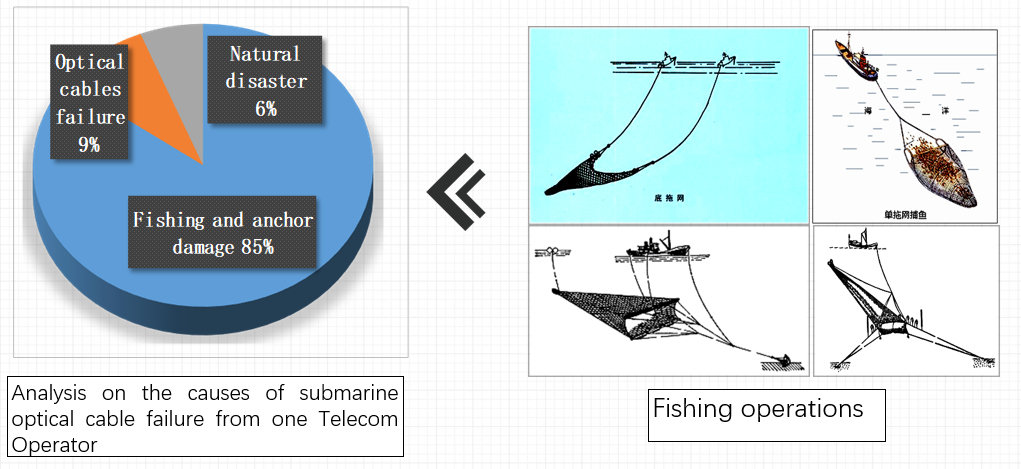

Major Needs: Statistics on common fault causes of submarine optical cables

After the submarine optical cables were laid, the failure rate caused by humans accounted for as high as 85%, and the losses were huge!

Status in China and Abroad

Most of the existing distributed fiber optic vibration sensing systems in China are based on Φ-OTDR technology, and the current applications are mainly concentrated in the field of perimeter security monitoring. The monitoring distance is generally limited to 30~50km. This type of technology is not suitable for submarine optical cable early warning field.

There have been no public reports on commercial cases abroad on early warning system of submarine optical cables hazards based on optical fiber sensing technology.

Since 2010, ShinewayTech has been one of the pioneer in China to carry out research and experiments on distributed optical fiber sensing technology.

On the premise of improving the original sensitivity and dynamic range, the sensing and early warning system (SEWS) developed by ShinewayTech, achieves a substantial increase in the monitoring length of the submarine cable to an unprecedented distance of 160 kilometers without repeaters, and the monitoring distance can be more than 1000 kilometers with repeaters.

Basic Methodology

With the existing optical fibers in submarine cables to build a sensing system that is sensitive to external hazards, conduct real-time monitoring, early warning and positioning of potential hazards and prevent them from happening. It can be combined with the maritime AIS system to track and stop the ships engaged in damaging within the corresponding submarine cable section, effectively preventing submarine cable disasters and improving the safety and survivability of submarine cables.

Key Usage

It solves the technical gap that current technical methods can only perform post-event fault location when hazards lead to cable breakage, but cannot provide early warning and positioning. It effectively improves the safety of submarine cables and greatly reduces submarine cable operation and maintenance costs.

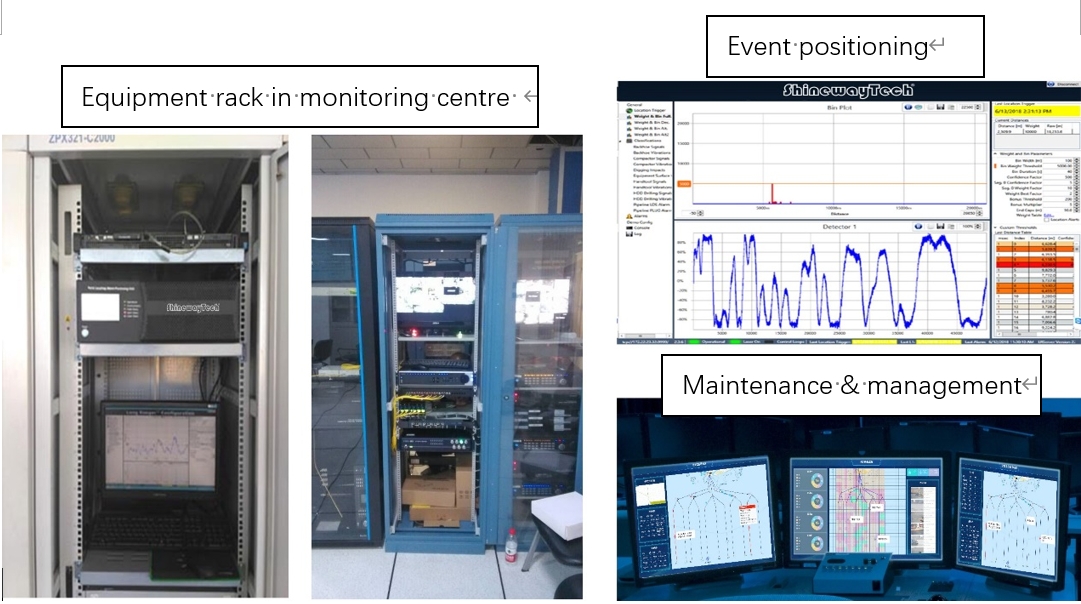

System Composition

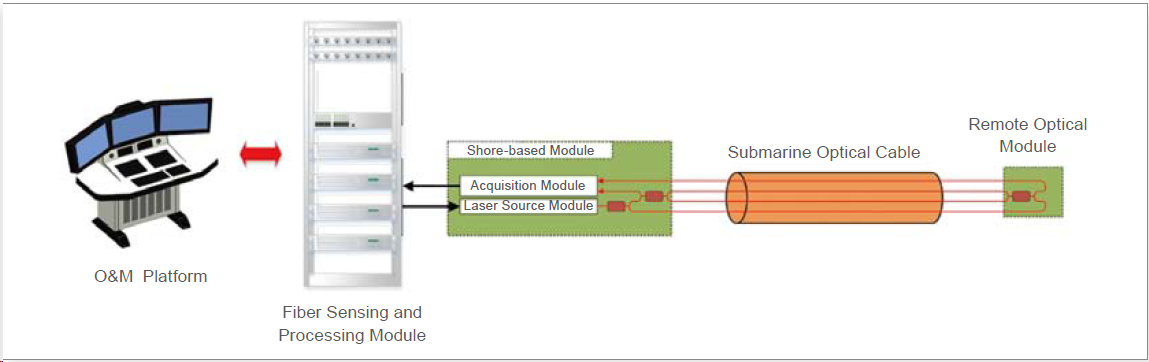

The SEWS system mainly includes three parts: the host of the system, the remote optical module, and the submarine optical cable as the sensor and transmission line of the system.

Core Equipment

Specifications

1、 SEWS-160 (160KM model)

• Wavelength: 1550nm

• Distance of monitoring: ≥ 160KM

• High spatial resolution: ≤ 50m

• Dynamic range: 120dB

• Frequency response range: 20 ~ 20KHz

• Warning latency time: < 6s

• Missed alarm rate: 0%

• False alarm rate: < 1%

2、SEWS-1000 (1000KM model)

• Wavelength: 1550nm

• Distance of monitoring: ≥ 1000KM

• High spatial resolution:

≤ 50m within 100KM

≤ 200m over the entire fiber span

• Dynamic range: 120dB

• Frequency response range: 20 ~ 20KHz

• Warning latency time: < 10s

• Missed alarm rate: 0%

• False alarm rate: < 1%

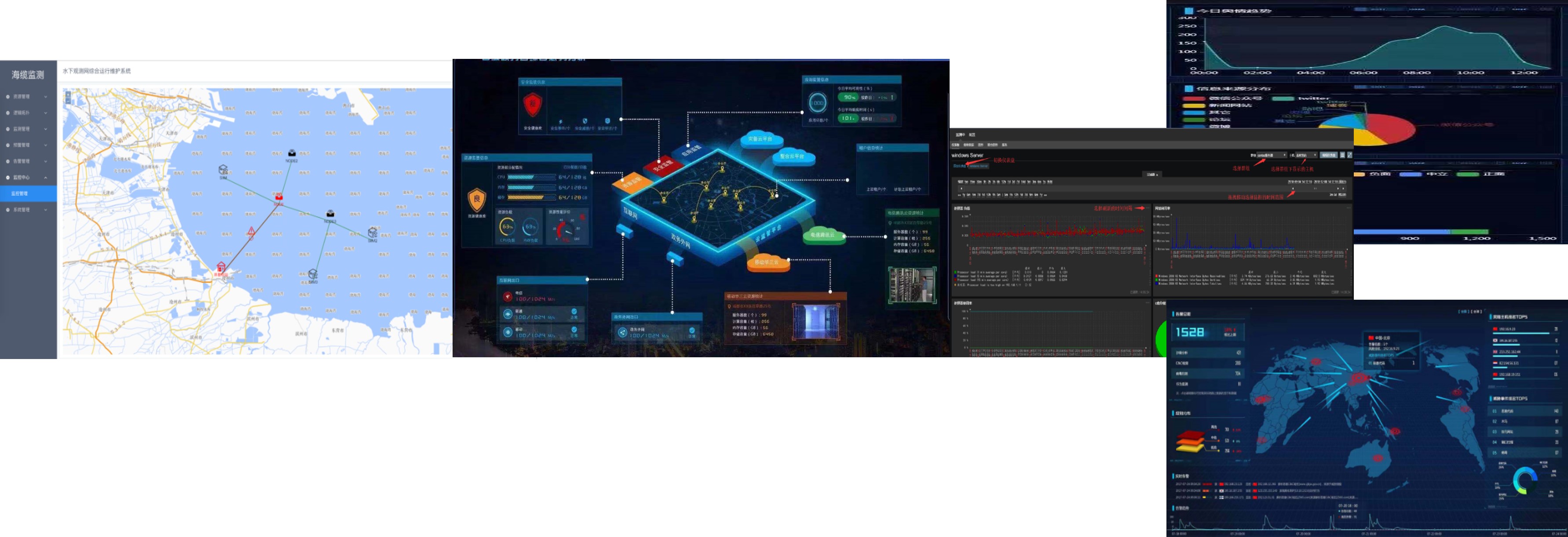

Safety Monitoring and Early Warning System of Submarine Optical Cables

Key Functions

1. System functions: information monitoring, display and control of submarine optical cable networks

2. Special equipment monitoring and management: whole operating status monitoring and management of submarine connection equipment, branches, repeaters, sensors, hydroacoustic communications and other equipment

3 . Hazard early warning: Intelligent analysis and hazard early warning, early prediction, effectively improves the safety and survivability of submarine cables

4. Data interface integration: It can be unified with AIS maritime system, ship routing monitoring system, etc. to realize the integration of underwater situation and surface situation

5. Role management: O&M administrator rights configuration and security policy management

6. Auxiliary decision-making: top-level management and decision-making assistance functions of other systems

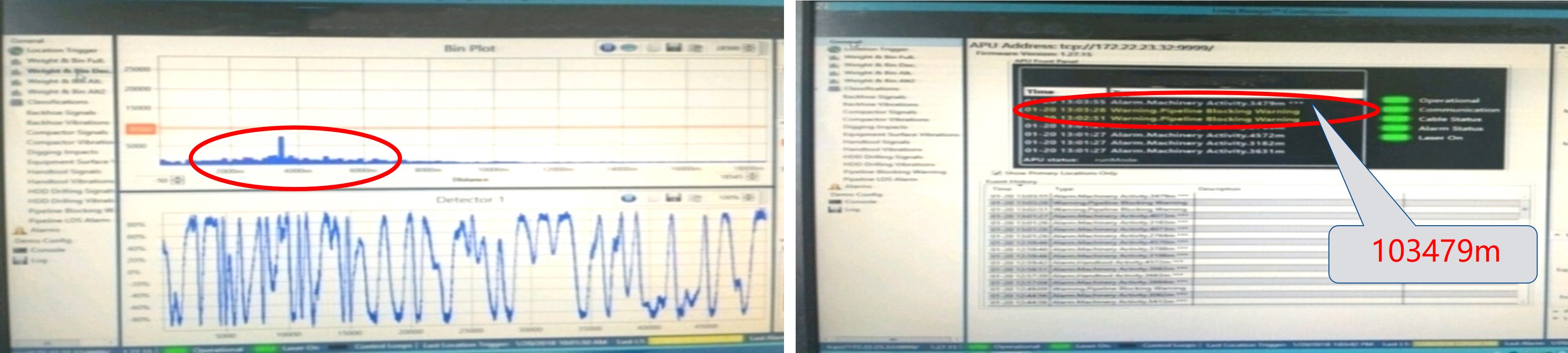

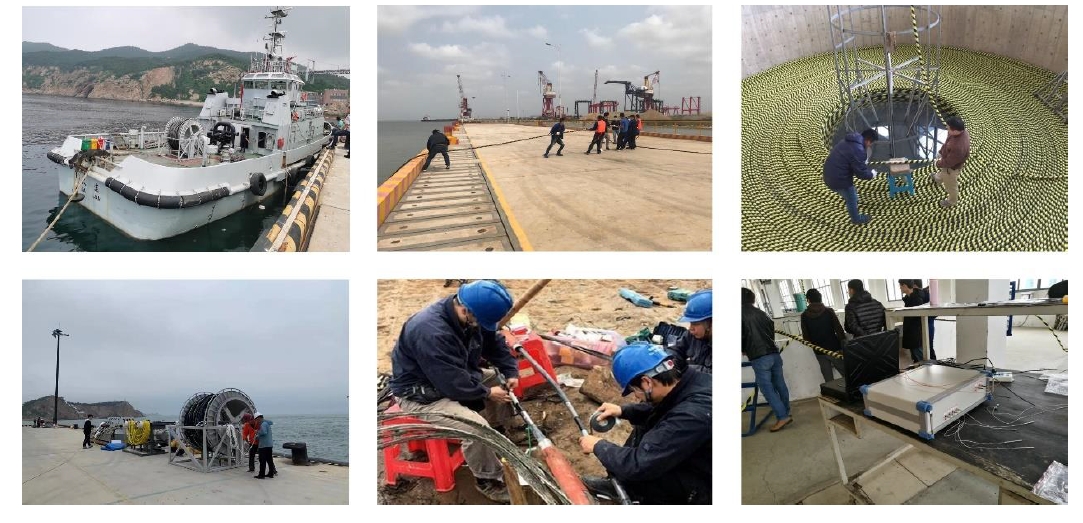

Deployed projects:

1. Monitoring of one submarine photoelectric composite cable with a monitoring distance around 100 kilometers.

2. One submarine photoelectric composite cable monitoring and early warning project monitors 11 submarine composite optical cables at different locations, each cable has 150 kilometer, and the total length of the submarine cable is 1,590 kilometers (no repeater monitoring method).

3. One submarine optical cable monitoring and early warning project, the total length of monitored submarine cables is about 300 kilometers (with repeater monitoring method).

Field Pictures

No information

FiberGuard